TOP GERMAN TECHNOLOGY

TOP GERMAN TECHNOLOGY

Success is achieved by enterprises that are able to tackle every task throughout the season using the lowest possible amount of resources and being effective with the time available. Equally, every penny counts when it comes to reducing production costs. DEUTZ-FAHR has developed the new 7 Series for such businesses. The two new 7 Series models deliver up to 246 HP and stand out for a range of trademark German characteristics: high quality, high precision and reliability combined with cutting-edge technology in terms of both cost-effectiveness and comfort.

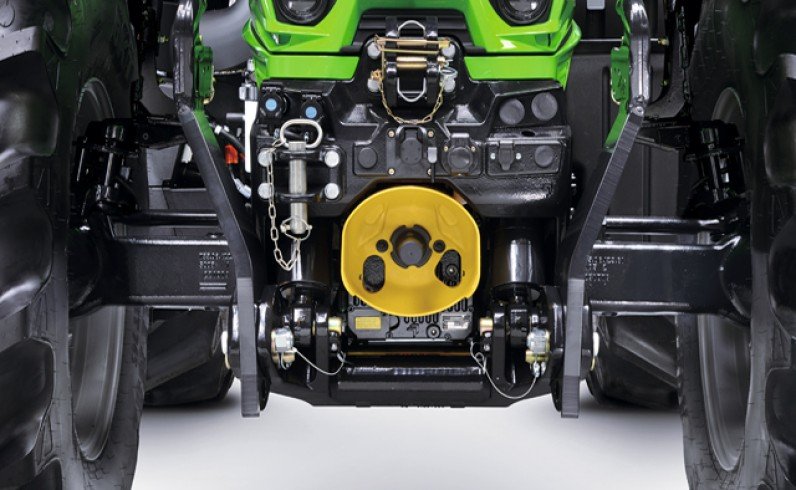

The 7 Series represents the culmination of highly innovative and intelligent tractor technology manufactured at our new facility in Lauingen, Germany, offering the exceptional comfort of the MaxiVision 2 cab, intuitive controls, a newly designed armrest, state-of-the-art precision farming systems, highly efficient engine and transmission technology, innovative axles and brakes which ensure optimal driving comfort and maximum safety. Furthermore, the hydraulic systems and lift capacity both front and rear, compliment the overall 7 Series specification making this tractor the ideal partner for increasing the productivity of professional contractors and agricultural businesses – both in the field and on the road. |

|

DCR

DCR

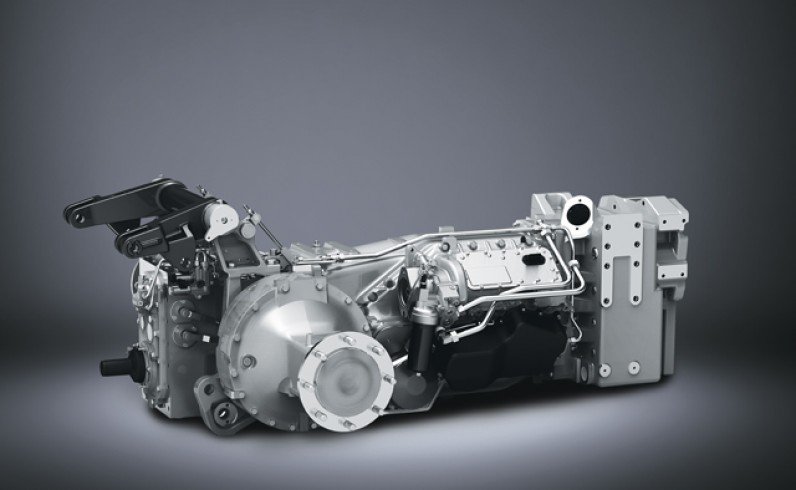

Deutz Common Rail. High pressure common rail injection system, with two lubricated injection pumps integrated in the engine block, and an innovative combustion chamber configuration for superlative power and torque over a wide range of engine speeds. |

|

SCR

SCR

Selective Catalytic Reduction. The tractor is equipped with a Selective Catalytic Reduction (SCR) exhaust cleaning system that utilises a 32.5% urea-water solution—AdBlue—for treating exhaust fumes. An additional AdBlue tank is fitted on one side of the tractor. |

|

B100

B100

Designed with specific technical solutions and constructed with special materials, the injection system is fully compatible with fuels containing up to 100% biodiesel. |

|

ENERGY SAVING

A system integrated in the hydraulic system which reduces thermal losses, improves efficiency and recovers energy that would otherwise be wasted. When the lift and distributors are not in use, a solenoid valve returns the hydraulic fluid flow to the transmission housing.

POWER BRAKES

A system ensuring an effective and immediate response from the brake system in all conditions with minimal pressure on the pedal by maintaining a constant pressure in the relative hydraulic circuit. |

|

ASM

ASM

An electronic system which automatically engages and disengages drive to the front wheels and the differential lock in relation to steering angle and speed. |

|

Over Speed

Over Speed

Optimised power curve usage, reduced consumption and improved driver comfort by maintaining lower engine speeds and using the engine at speeds close to maximum torque. |

|

Stop & Go

Stop & Go

A system maximising the potential of the Sense Clutch shuttle for superlative manoeuvrability. Ideal for jobs involving frequent stops and starts. |

|

Sense Clutch

Sense Clutch

Hydraulic reverse shuttle with two multiplate wet clutches and an electronic control unit. |

|

COMMANDER CONTROL

Joystick-controlled control functions. The operator can easily and conveniently control selected tractor functions.

SENSORS

This advanced technology tractor is equipped with several sensors monitoring the correct operation of all machine systems and functions. Sensor signals are collected and analysed by a control panel which adjusts tractor settings on the basis of this information in order to meet current needs.

ELECTRONIC ENGINE GOVERNOR

The system monitors a set of engine parameters, and optimises engine function by adjusting injection accordingly. Automated for total simplicity: lets the driver set, store and recall the most appropriate engine speed for the job in hand. |