|

Active Float System

Active Float System

Two sets of coil springs on the CA25 support up to 97% of the header weight, which allows for instant float response of the header over rolling and uneven terrain. In addition to the already amazing flex action of the FlexDraper®, the Active Float provides 4.8° of lateral float and 7" (178 mm) of vertical float independent of the combine feeder house. This prevents the header from getting caught up in bumpy fields, which leads to uneven cutting and unnecessary dirt ingestion. MacDon's Active Float System keeps our headers true to the ground for a nice, even cut and ensures smooth, consistent, heads-first feeding to the combine. |

|

True Multi-Crop Heade

True Multi-Crop Heade

The FlexDraper® switches easily from flex to rigid applications with the quick flip of a lever. Harvesting cereals, oil seeds, beans and just about any crop in any condition makes the MacDon FlexDraper® a true multi-crop header. |

|

Flex-Float Technology®

Flex-Float Technology®

MacDon's Flex-Float Technology® is what makes the FlexDraper® perform so well. The flex advantage comes from a fixed reel-to-cutter bar relationship, and the float advantage comes from instant float response of the header. See the next page for more details. |

|

Reel To Cutterbar Relationship

Reel To Cutterbar Relationship

The MacDon FD75 FlexDraper® features a fixed reel-to-cutterbar relationship. A small critical gap between the reel fingers and the cutter bar is maintained at all times, even at extreme flex. This small gap ensures smooth, consistent, heads-first feeding of the crop over the entire width of the FlexDraper® . |

|

Reel Performance

Reel Performance

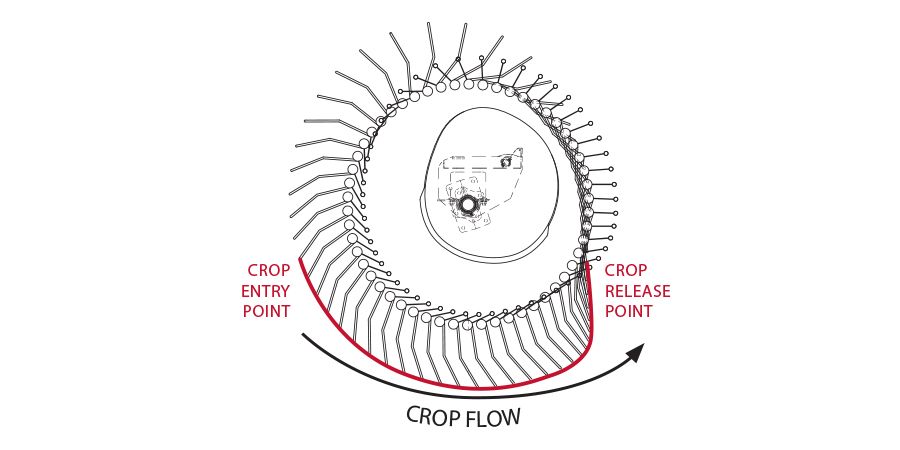

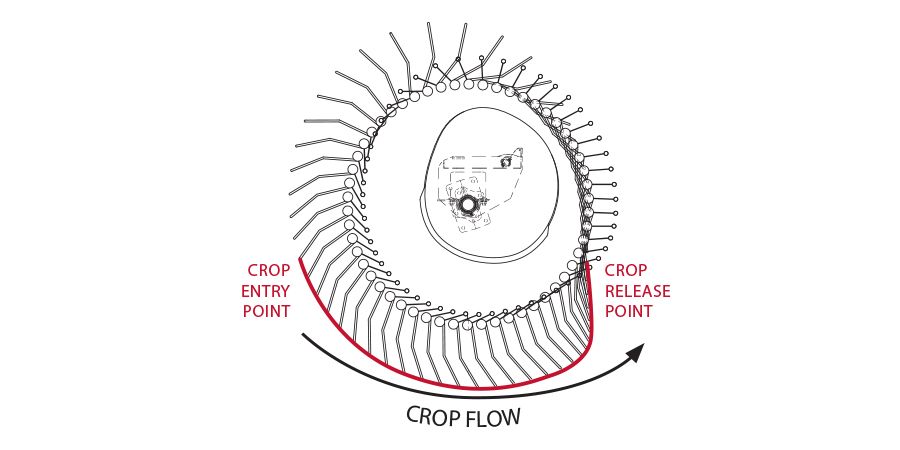

MacDon's patented pick-up reel has been engineered to deliver outstanding performance. The unique movement of this reel and the reel fingers confidently picks up and gently places crops onto the draper. Along with 4 cam positions, header tilt control, and fore-aft reel positioning, this reel can be adjusted to meet the toughest harvesting challenges and helps to deliver smooth, consistent, heads-first feeding of the crop to the combine |

|

True Ground Following

True Ground Following

The MacDon FD75 is a floating, three-section flexible header with a split reel. This allows the entire header frame, cutterbar, and reel to follow ground contours as a unit, flexing up to 10" (245 mm) on either end while maintaining a close reel-to-cutterbar relationship. This unique three-section design lets the FD75 FlexDraper® deliver smooth, consistent, heads-first feeding to the combine, even at extreme flex. |

|

Cutterbar Poly

Cutterbar Poly

This kit is a compression molded component that has very high wear characteristics. It is used when cutting low podding crops like soybeans, lentils, or other lodged crops. The smooth design characteristics make this kit ideal for muddy harvesting conditions by reducing the likelihood of mud building up on the cutterbar.

This kit is available for all header sizes. |

|

Advanced Draper & Seal Technology

Advanced Draper & Seal Technology

MacDon’s draper system features heavy-duty drive components designed to handle the heaviest crop loads. The V-guide draper tracking system keeps the drapers tracking perfectly, moving the crop quickly and constantly across the drapers. MacDon double V-guide drapers are reversible for twice the amount of in-field use. |

|

Upper Cross Auger Option (Combine)

Upper Cross Auger Option (Combine)

Attached in front of the back tube, the upper cross auger improves feeding of the crop to the center in heavy, bushy, and high-volume crop conditions. |

|

Transport & Stabilizer Package Option

Transport & Stabilizer Package Option

This kit will allow you to transport your draper header;from farm-to-field and then quickly switch to field Stabilizer Wheel position by one person. The Transport Package is a simple self-supporting unit with very little hitch weight for simpler hitching. The transport tow pole is a two piece unit that requires no tools to assemble / disassemble and stores on the back tube of the header during harvesting operation. The Stabilizer Wheel application is ideal for cutting off the ground, by stabilizing the header in undulating ground conditions.

This kit can be used on 30’ (9.1m) and larger headers. |

Active Float System

Active Float System True Multi-Crop Heade

True Multi-Crop Heade Flex-Float Technology®

Flex-Float Technology® Reel To Cutterbar Relationship

Reel To Cutterbar Relationship Reel Performance

Reel Performance True Ground Following

True Ground Following Cutterbar Poly

Cutterbar Poly Advanced Draper & Seal Technology

Advanced Draper & Seal Technology Upper Cross Auger Option (Combine)

Upper Cross Auger Option (Combine) Transport & Stabilizer Package Option

Transport & Stabilizer Package Option