| Monday | 7:30AM - 8:00PM |

| Tuesday | 7:30AM - 8:00PM |

| Wednesday | 7:30AM - 8:00PM |

| Thursday | 7:30AM - 8:00PM |

| Friday | 7:30AM - 8:00PM |

| Saturday | 8:00AM - 8:00PM |

| Sunday | 9:00AM - 8:00PM |

| Monday | 7:00AM - 6:00PM |

| Tuesday | 7:00AM - 6:00PM |

| Wednesday | 7:00AM - 6:00PM |

| Thursday | 7:00AM - 6:00PM |

| Friday | 7:00AM - 6:00PM |

| Saturday | 8:30AM - 5:30PM |

| Sunday | Closed |

new Inventory

Kuhn - VB 3165 OPTIFEED

-

ID # 27949687

- Back ID:27949687

- Book a Demo

- Get Directions

|

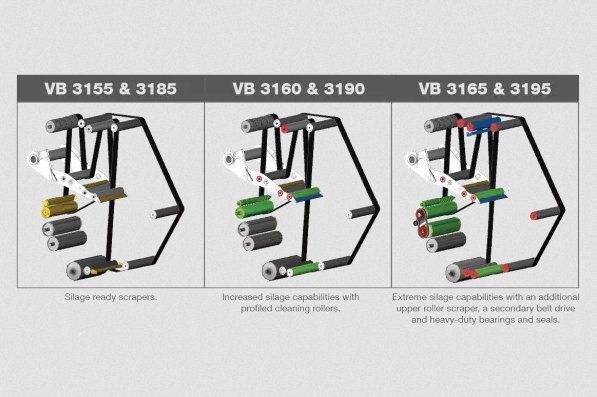

KUHN variable chamber round balers take high-density baling to the next level. Whether you’re a farmer producing a couple hundred bales each season or you’re a custom operator producing thousands of bales, there’s a KUHN VB round baler for you. The VB 3100 Series offers a complete range of variable chamber round balers to suit any size operation, any budget and any type of crop. If you’re looking to bale mostly dry materials such as hay and straw, the VB 3155 and 3185 balers are the right round balers for the job. These models will provide you with the capability and performance you expect, without any extras to weigh you down. The VB 3160 and 3190 Premium round balers work well handling anything from heavy silage to dry cornstalks, with the added convenience of full ISOBUS control. The KUHN VB 3165 and 3195 Premium XD round balers are designed to work in the toughest conditions throughout the world and are ideal for custom operators who need extra density in straw. Built for high-volume hay production, these models feature the most heavy-duty components to keep you producing rock-hard bale after bale, day after day. |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| VB 3155 DIRECT | VB 3155 OPTIFEED | VB 3155 OPTICUT | VB 3160 DIRECT | VB 3160 OPTIFEED | VB 3160 OPTICUT | VB 3165 OPTIFEED | VB 3165 OPTICUT | |

|---|---|---|---|---|---|---|---|---|

| Minimum machine weight | 5,400 lbs (2,450 kg) | 6,400 lbs (2,900 kg) | 6,725 LBS (3,050 kg) | 5,600 lbs (2,540 kg) | 6,800 lbs (3,040 kg) | 7,140 lbs (3,240 kg) | 7,100 lbs (3,220 kg) | 7,540 lbs (3,420 kg) |

|

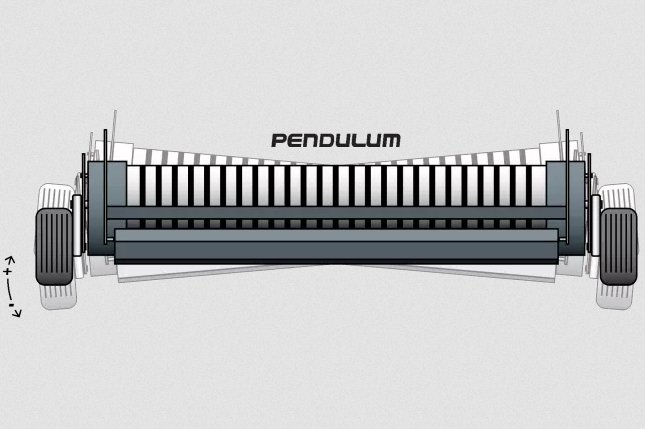

Intake Options to Meet Your Operation’s Needs

All VB 3100 models feature a wide pickup with standard crop roller. The pickup is designed to maximize the full capacity of the machine. With a working width of 83 or 91 inches, the machine is capable of working in all windrows and will not let you down, even in the toughest conditions. Straight pickup tines help release the crop and reduce crop wrapping. The pickup roller compresses the crop against the pickup tines reducing friction, thus reducing leaf loss and increasing baler efficiency by evening out the windrow. |

|

The direct feeding system is an unrestricted intake unit for maximum capacity in all crop conditions. In heavier conditions, like big wide straw or silage windrows, the top roller is acting like a pre compactor which is powered by the primary driveline of the baler. There are no stuffer fingers which can disturb the flow and therefore limit the intake capacity. This generates a huge input potential and prevents plugging of the unit resulting in a high output and minimum downtime. |

|

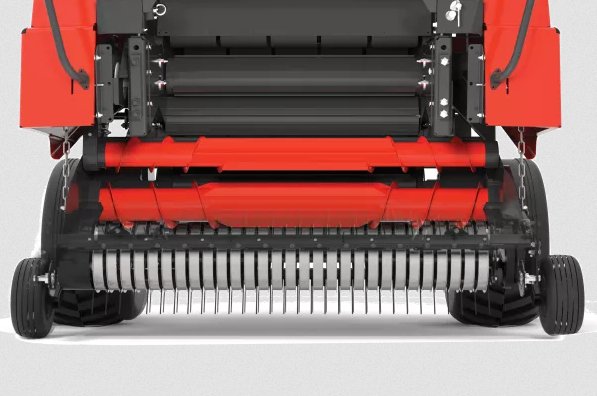

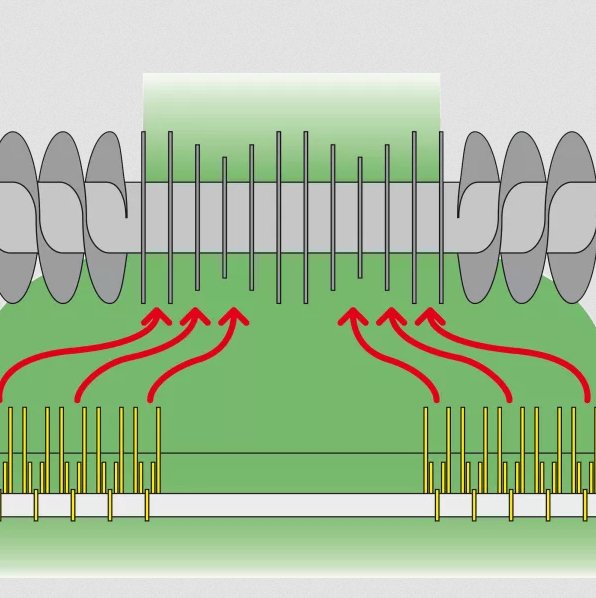

Available across the entire VB 3100 range is our patented Integral Rotor Technology found on OptiFeed and OptiCut models. This simple, low-maintenance intake system guarantees an enormous throughput capacity at all times. The short distance between rotor and pickup tines maintains consistent crop flow. The design of this force-fed intake makes higher forward speeds possible for increased productivity and reduces crop damage. The Integral Rotor on all models, except VB 3155 & 3185 units, are provided with rotor tines made out of Hardox® wear plates. Hardox combines extreme hardness and toughness to reduce rotor tine wear. Longer wearing life of the rotor tines will help to provide time and money savings for the operator. |

|

The OptiFeed rotor, with single feeding tines and integrated augers, provides a consistent flow of crop into the bale chamber. This rotor design helps even out incoming windrows for consistent bales every time. |

|

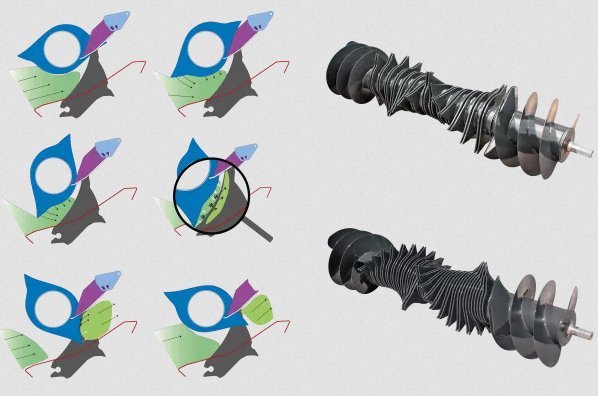

The OptiCut (OC) cutting rotors are designed for unlimited intake capacity and excellent cutting quality. KUHN (OC) cutting rotors, with elliptical shaped rotor tines, are acknowledged by users as one of the best cutting systems on the market. The silage is guided and drawn down to the knives from an early stage which improves flow and cutting performance and also prevents unwanted plugging.

OptiCut 14

OptiCut 23

|

|

Consistent, Firm Round Bales

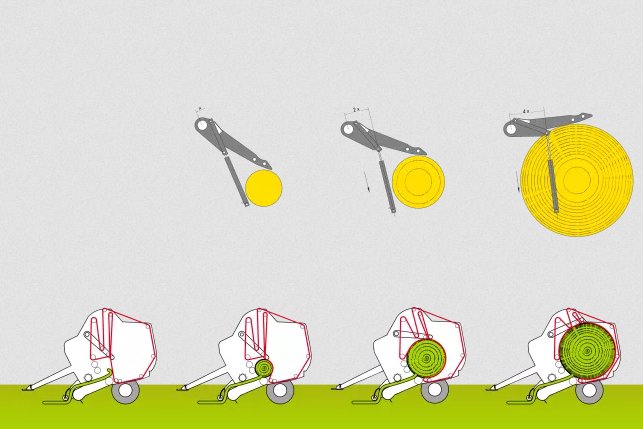

Progressive Density – The KUHN Solution

Progressive Density – The KUHN Solution

The Progressive Density system has proven its value on all KUHN VB balers. The system increases tension as the bale grows providing a firm bale with a tough outer shell. |

|

The 5 belt, 3 roller design of the VB 3100 Series bale chamber ensures fast, consistent bale formation whatever the intake system. The aggressive profile of the top chamber roller improves crop contact and reduces crop loss. The front segment of the baler is fitted with a large smooth roller and driven cleaning roller that prevents crop build up at the front of the machine. The unique mix of the KUHN Progressive Density system and smart bale chamber design guarantees perfect bale formation every time. |

|

KUHN Net & Twine Solutions

One of the final steps in creating the perfect bale is the wrap. Securing a bale to protect it from the elements and from losing its shape is one of the most crucial steps. The less time required to secure the bale, the higher the baling operation output. KUHN net & twine solutions guarantee reliable and secure wrapping. |

|

The net wrap with active stretch technology ensures a firm bale shape with constant net tension throughout the entire wrapping cycle. The net is fed into the front of the bale chamber to ensure it is taken by the bale immediately. A second net roll storage enables the operator to carry a sufficient net supply for a longer working day. Changing of the net roll can be done easily while standing safely on the ground.

|

|

When using the double twine arm system, the tying cycle time is reduced to a minimum. In the twine tying cycle, both of the twines start at the bale edge and overlap before moving to the center of the bale. In the center of the bale they overlap again, this ensures the twines are fixed and that there are no loose ends. |

| Download Brochure | Download |